This proposal for a rooftop intervention atop Martel College at Rice University incorporates both urban farming and rainwater collection through a folded structural system. The structure houses the complete tea production process, from planting it all the way to drinking it. The intervention currently occupies about a third of the roof as phase one of a long-term, multi-phase project.

This project is a collaboration with Juhi Parikh.

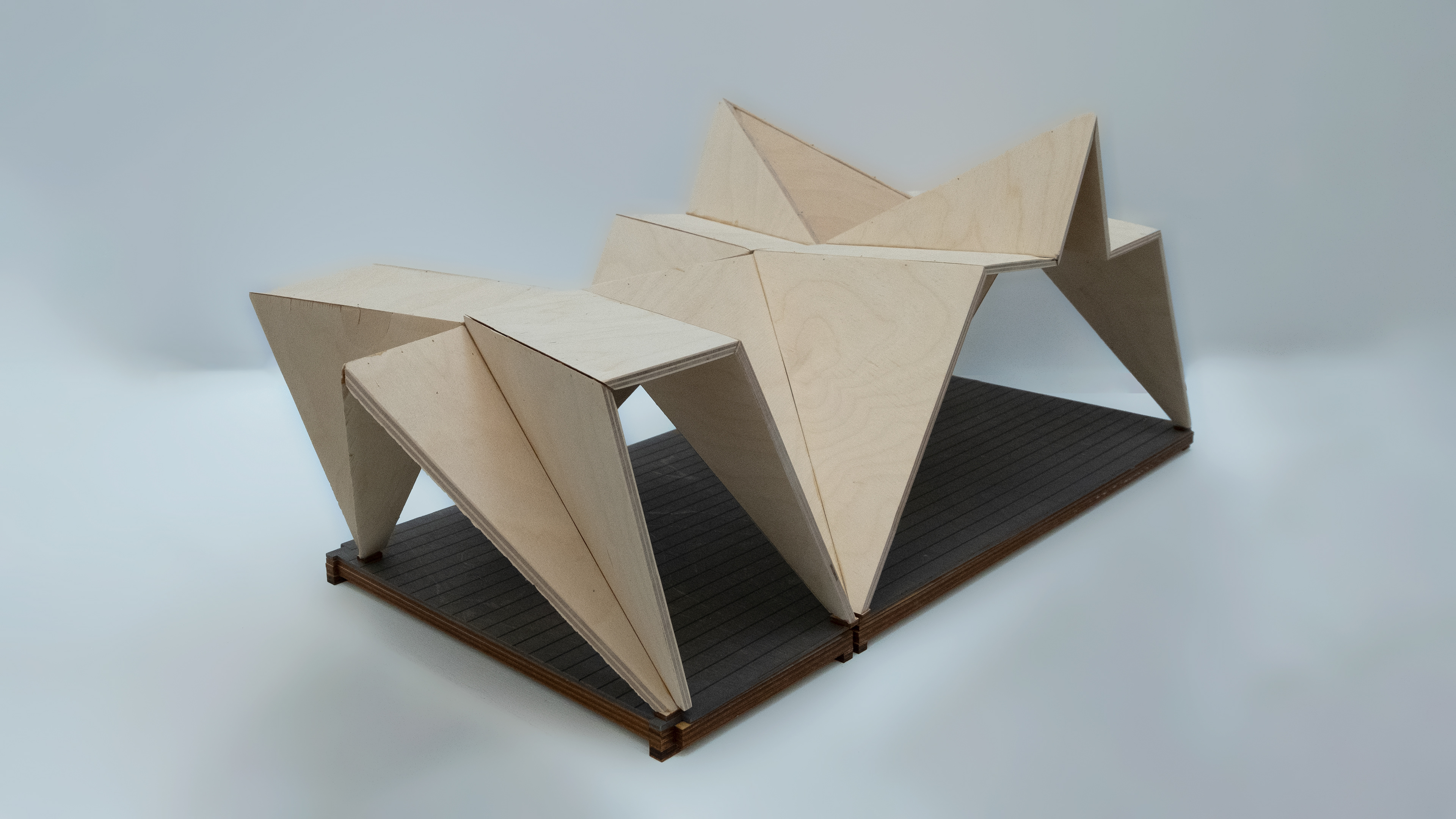

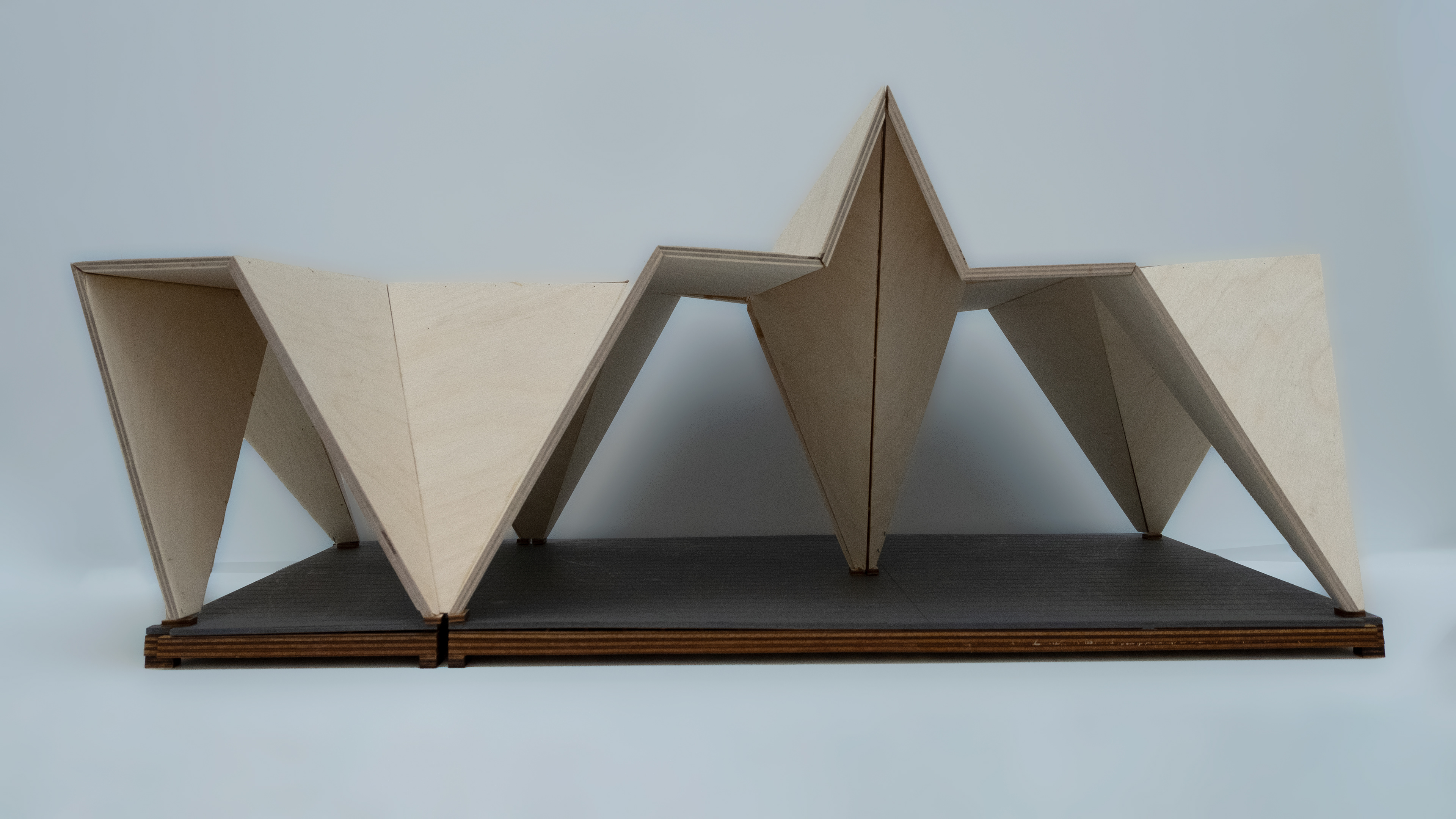

EXPERIMENTAL MODULES

An initial origami study uses both curved and linear folding and demonstrates the structural consequences of a number of variables. The curved folding developed into a triangulated approach in an effort to simplify the geometries and create a base set of modules that could be aggregated in infinite variations.

ADAPTATION TO SITE

Upon analyzing the irregular structural grid of Martel College, the initial module set was re-iterated and used to develop the first phase of the project.

RESOLUTION

The folded structure takes the form of a linear sheltered bay with three extensions on one side and four alcoves on the other. This creates porous spaces on the extension side that are occupied with planters featuring the camellia sinensis plant, which is the primary tea-producing plant. They thrive in moist, subtropical climates, with precautions like partial shading from long exposure to the hot sun; as such, slatted wooden canopies and mesh walls provide the trees enough sunlight without over-exposing them. On the other side, each alcove features an array of south-facing terraced planter boxes used to grow smaller herbs and flowers. The variation in the height of the boxes allows some to be more sheltered from the sun to accommodate different plants’ needs. Both these planter walls and the planter boxes opposite them feature an integrated drip irrigation system for streamlined watering procedures.

ASSEMBLY

Due to the large modules and the size constraints of a standard truck, we compromised between total prefabrication and total on-site assembly. Four prefabricated typologies that recur throughout the aggregation are easily transported on trucks accompanied by other necessary pieces. We approximate that 6 truckloads would be needed for all the materials required. The module construction starts with the prefabricated pieces, which are attached by connective panels. The modules, made out of CLT, are assembled on the ground to provide the flexibility to manipulate and flip them over, and then, once they are assembled, waterproofed, and clad, they are lifted to the roof by a crane and placed on a porous, topographical deck system.

TECHNICAL

The water used throughout the intervention comes from the catchment system with four central basins. The form of these basins provides structural support for the roof while allowing a small quantity of water to be stored for irrigation purposes. The irrigation system also doubles as a space cooling system, with misting nozzles along the overhead pipe routing. The other structural points of the folded system also feature drains, from which a network of pipes run to a tank to the ground level. This larger quantity of water can then be pumped back up to the roof as needed.

EXPANSION PHASES